Leave Your Message

Request a Quote

In recent years, the importance of efficient air and fluid filtration systems has gained significant traction within industrial applications. Bag filtration, a widely adopted method for separating particulate matter from gases and liquids, remains at the forefront of these advancements. According to a report by MarketsandMarkets, the global bag filter market is expected to reach $3.3 billion by 2025, reflecting a steady growth rate driven by increasing regulatory standards and the need for improved operational efficiencies across various industries.

Effective bag filtration techniques not only enhance compliance with environmental regulations but also contribute to energy savings and process optimization. A study by the U.S. Environmental Protection Agency highlights that industries employing advanced bag filtration systems can achieve up to a 30% reduction in operating costs, making it a vital component in sustainable practices. Furthermore, the adoption of innovative materials and designs in bag filter systems has led to improved performance metrics, enabling industries to better manage waste and emissions while maintaining productivity levels.

As we explore the top bag filtration techniques for 2025, it becomes clear that the continuous evolution of this technology is key to meeting the challenges posed by modern industrial demands. Emphasizing efficiency, adaptability, and environmental responsibility, bag filtration is poised to play an essential role in the future landscape of industrial operations.

Bag filtration techniques play a crucial role in various industrial applications, enhancing efficiency and ensuring compliance with stringent environmental regulations. A report by the Global Market Insights estimates the air filtration market, which includes bag filtration systems, to reach $28 billion by 2025, driven by increased awareness of air quality and rising industrial activities. Bag filters, known for their effectiveness in capturing particulate matter, have become essential in sectors such as pharmaceuticals, food processing, and manufacturing, where maintaining a clean environment is paramount.

One of the key advantages of bag filtration systems is their ability to handle high volumes of air while delivering low-pressure drop characteristics, which results in energy savings. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), modern bag filters are capable of achieving efficiency rates of up to 99.9% for particulate removal. This level of efficiency not only aids in improving product quality but also prolongs equipment lifespan by minimizing dust accumulation. Moreover, as industries increasingly shift towards greener operations, the incorporation of bag filtration techniques aligns with sustainability goals by reducing emissions and promoting a cleaner workspace. The continuous advancement in filter media technology is expected to further enhance these systems' performance and efficiency in the coming years.

The efficiency of bag filters in industrial applications is influenced by several key factors that directly affect their performance and durability. One significant factor is the type of filter media used, which determines the filter's ability to capture various particulate sizes. High permeability fabrics can enhance airflow and reduce energy consumption, while tighter weaves can improve filtration by trapping finer particles. Additionally, the choice of media should consider factors such as resistance to chemical degradation and temperature stability, ensuring that the filter operates effectively under diverse industrial conditions.

Another critical aspect is the design and maintenance of the filtration system. Optimal bag sizes and configurations can minimize dead zones and ensure even flow distribution, which is crucial for maximizing filtration efficiency. Regular maintenance, including cleaning and timely replacement of bag filters, helps in maintaining consistent performance and extending the lifespan of the filtration system. Moreover, controlling operational parameters, such as airflow rate and humidity levels, can significantly influence the overall efficiency of bag filters, thereby enhancing the effectiveness of the filtration process in various industrial settings.

| Filtration Technique | Efficiency (%) | Dust Load Capacity (g/m²) | Airflow Rate (m³/h) | Maintenance Frequency (Months) |

|---|---|---|---|---|

| Pleated Bag Filters | 99.99 | 300 | 4000 | 6 |

| NanoFiber Filters | 99.95 | 250 | 3500 | 12 |

| Water Resistant Filters | 99.90 | 400 | 4200 | 8 |

| Electrostatic Filters | 99.80 | 500 | 3800 | 15 |

| High Efficiency Filters | 99.97 | 450 | 3900 | 10 |

Recent advancements in material technology are significantly enhancing the efficiency and performance of bag filtration systems used in various industrial applications. Innovations in fabrics, such as the development of high-strength synthetic fibers, have led to bags that not only withstand extreme temperatures and corrosive environments but also provide superior filtration efficiency. These materials exhibit enhanced resistance to abrasion and clogging, which translates to reduced maintenance costs and longer service life for filtration systems.

Furthermore, the integration of nanotechnology into filtration media is revolutionizing the industry by allowing for the creation of filters with superior particle capturing capabilities. Embedded nanoparticles can improve the surface characteristics of filter materials, enabling them to target smaller particulate matter that traditional filters struggle to contain. This development is particularly crucial in industries where air quality and pollutant control play a vital role, such as pharmaceuticals and food processing. As these advanced materials become more widely available, they promise to elevate the standards of air quality management in industrial settings, ultimately contributing to improved operational efficiency and compliance with environmental regulations.

In the realm of industrial applications, bag filtration techniques have demonstrated a remarkable ability to cater to the unique demands of various sectors. When comparing filtration methods across industries, it becomes evident that each medium and design plays a vital role in achieving optimal efficiency and performance. For instance, industries such as pharmaceuticals and food processing often prioritize stringent cleanliness and particulate removal, prompting the adoption of high-efficiency particulate air (HEPA) filters. These filters are designed to capture microscopic particles and maintain the integrity of the final product.

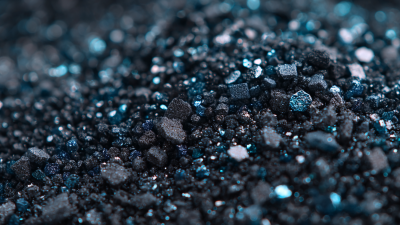

Conversely, industries like construction and mining may require more robust solutions capable of handling larger particulate loads and harsh environmental conditions. In such applications, durable synthetic or fiberglass filters are frequently employed, designed to withstand aggressive dust and abrasive particles while still maintaining airflow. The choice of filtration media and design directly impacts not only the operational efficiency of equipment but also the overall health and safety standards within the workplace, showcasing the necessity for a tailored approach in selecting bag filtration techniques based on specific industrial requirements.

Maintaining bag filters is crucial for ensuring optimal performance and longevity in industrial applications. To achieve this, regular inspections should be conducted to identify any signs of wear or damage. Monitoring pressure drops across the filter media is essential, as an increase in pressure can indicate clogging or buildup that needs to be addressed promptly. Cleaning or replacing filters as needed based on inspection results helps maintain airflow efficiency and prevents unexpected failures.

Another best practice involves implementing a scheduled maintenance program that includes proper cleaning techniques, such as pulse jet cleaning or reverse air cleaning, tailored to the specific application and type of filter media. Additionally, training personnel on best practices and procedures for handling bag filters ensures that they are equipped to make informed decisions regarding the maintenance process. By adhering to these strategies, facilities can enhance the operational efficiency of their filtration systems and extend the lifespan of bag filters, ultimately leading to improved productivity and reduced maintenance costs.