Leave Your Message

Request a Quote

Air quality is a pressing concern in today's industrial landscape. According to the US Environmental Protection Agency, poor air quality causes millions of health issues annually. Bag filtration systems play a crucial role in enhancing air quality. They effectively capture harmful particles and pollutants, ensuring cleaner environments.

Dr. Emily Rogers, a leading expert in air filtration technologies, emphasized, “Bag filtration is essential for mitigating airborne contaminants.” Her research indicates that implementing efficient bag filtration can reduce particulate matter by over 95%. However, selecting the right system is not straightforward. Many organizations struggle to balance cost and performance.

While bag filtration systems are effective, they require regular maintenance and monitoring. This poses challenges for facilities with limited resources. Moreover, some systems may not be suitable for all types of pollutants. The ongoing evolution of filtration technologies means businesses must continually assess their air quality needs. As industries evolve, so must our approach to bag filtration.

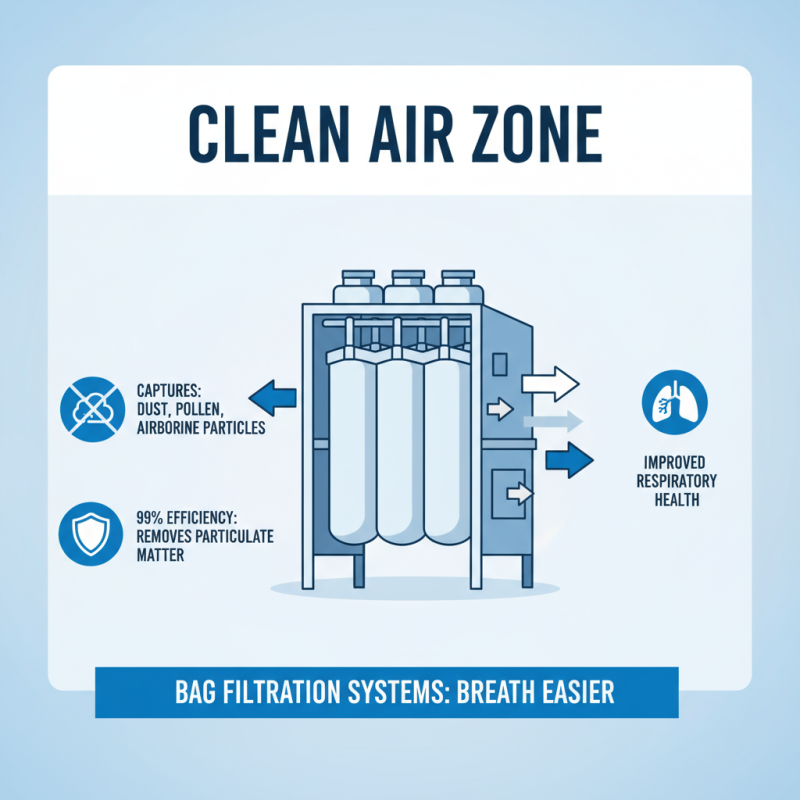

Bag filtration systems play a crucial role in improving air quality. They capture dust, pollen, and other airborne particles through the use of fabric bags. Studies show that these systems can remove up to 99% of particulate matter from the air. Such efficiency helps reduce respiratory issues among individuals.

According to recent indoor air quality reports, the right filtration system can make a world of difference. Poor air quality is linked to health problems like asthma and allergies. Many homes and workplaces still lack adequate filtration. It's alarming that a significant number of places do not prioritize proper systems. Many buildings use outdated filters, which may not comply with current standards.

Inevitably, bag filtration systems need regular maintenance. Clogged filters can lose efficiency, making air quality worse. Awareness is still low about the impact of clean air on overall health. Investing in top-tier filtration should be a norm. Not all systems are created equal. Some methods may require troubleshooting. The goal should always be clear: to breathe cleaner, healthier air.

When considering bag filtration systems, key features can significantly enhance air quality. A robust filtration capability is essential. Look for systems that capture fine particles and allergens. High-efficiency filters can trap dust, pollen, and smoke. This is especially important in urban environments where air quality may be poor.

Another critical feature is easy maintenance. A system that requires less frequent filter changes will save both time and money. Consider how easy it is to replace bags and access the filter compartments. Additionally, noise levels during operation are worth noting. A quiet system maintains a peaceful environment, making it suitable for homes and workplaces.

Energy efficiency is another point of reflection. Some models may consume more energy than expected. A balance between power use and filtration quality is essential. Careful evaluation of performance ratings can prevent regret later. Overall, these features lead to a more effective air filtration system. Remember to weigh the pros and cons before making a decision.

Bag filtration systems play a vital role in enhancing air quality. Their efficiency often varies based on the type of filter used. Different bag filters cater to diverse needs and applications. Some are designed for industrial settings, while others serve commercial environments. Understanding these types is crucial for effective air management.

One common type is the polyester filter. It’s cost-effective and suitable for general air filtration. These filters capture large particles effectively, but they may not perform well with smaller pollutants. On the other hand, HEPA filters excel in capturing fine particles, but they can be more expensive and require regular maintenance. Users must weigh the pros and cons of each type carefully.

Bag filters also come with various pleat configurations. This design aspect affects air flow and dust retention. A filter with too few pleats may clog quickly, leading to inefficiency. Meanwhile, filters with many pleats can handle more dust but may impede air flow. Choosing the right configuration is essential. Some applications may require trade-offs between air flow and filtration efficiency. It's an ongoing challenge to select the best filter for specific air quality needs.

| Type of Bag Filter | Applications | Efficiency (%) | Temperature Range (°C) | Lifespan (Months) |

|---|---|---|---|---|

| Polyester Bag Filter | Dust Collection in Woodworking | 99% | -20 to 80 | 24 |

| Nomex Bag Filter | Cement Production | 98% | -20 to 200 | 18 |

| PTFE Bag Filter | Food Processing and Pharmaceuticals | 99.9% | -40 to 260 | 36 |

| Acrylic Bag Filter | Metal Processing | 95% | -20 to 150 | 30 |

| Glass Fiber Bag Filter | Chemical Plants | 99% | -20 to 300 | 24 |

Bag filtration systems play a crucial role in maintaining air quality. Regular maintenance ensures they operate efficiently and last longer. It's reported that proper upkeep can extend the life of these systems by up to 50%. This is significant, considering the investment associated with installation.

Clean filters improve performance and energy efficiency. According to the U.S. Environmental Protection Agency, well-maintained filters can save up to 15% in energy costs. On the flip side, neglecting maintenance can lead to reduced air quality and increased operational costs. Monitoring filter conditions frequently is vital. Many users forget to check bag status until issues arise.

Additionally, regular cleaning and timely replacements are necessary, but often overlooked. Some maintenance schedules fall short of recommended frequencies. A thorough understanding of your system's specifications aids in optimizing its performance. Reports indicate that systems suffering from poor maintenance can operate at only 70% efficiency. Thus, identifying and addressing maintenance needs is essential for sustaining effective air quality improvement.

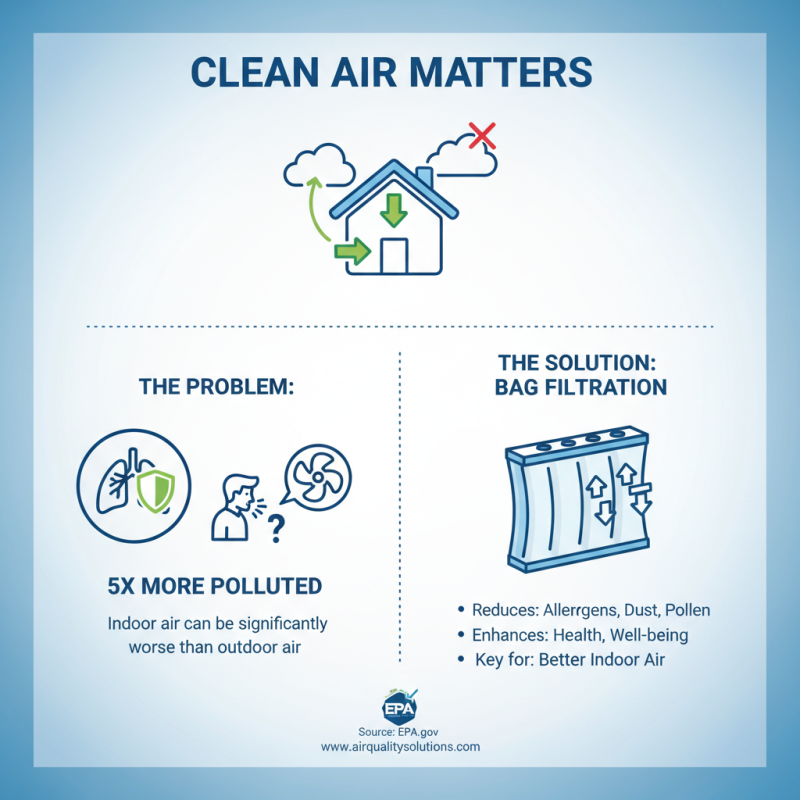

In today's world, air quality is a pressing concern. Bag filtration systems are key players in improving indoor air environments. According to the Environmental Protection Agency, indoor air can be five times more polluted than outdoor air. Ensuring effective filtration can reduce allergens and particulate matter, enhancing overall health.

A comparative analysis of bag filtration systems reveals significant differences in performance. Some systems can capture particles down to 0.3 microns. In contrast, others struggle with larger contaminants. The efficiency of these systems often varies based on design and material used. For instance, high-efficiency particulate air (HEPA) filters are known for superior performance but can be more costly.

Cost and maintenance are also vital considerations. Some systems require more frequent bag changes, which could lead to higher long-term expenses. It's essential to assess these factors, as users may overlook them in favor of upfront savings. An informed choice often leads to better air quality and health outcomes, but many consumers are still finding their way through this complex landscape.