Leave Your Message

Request a Quote

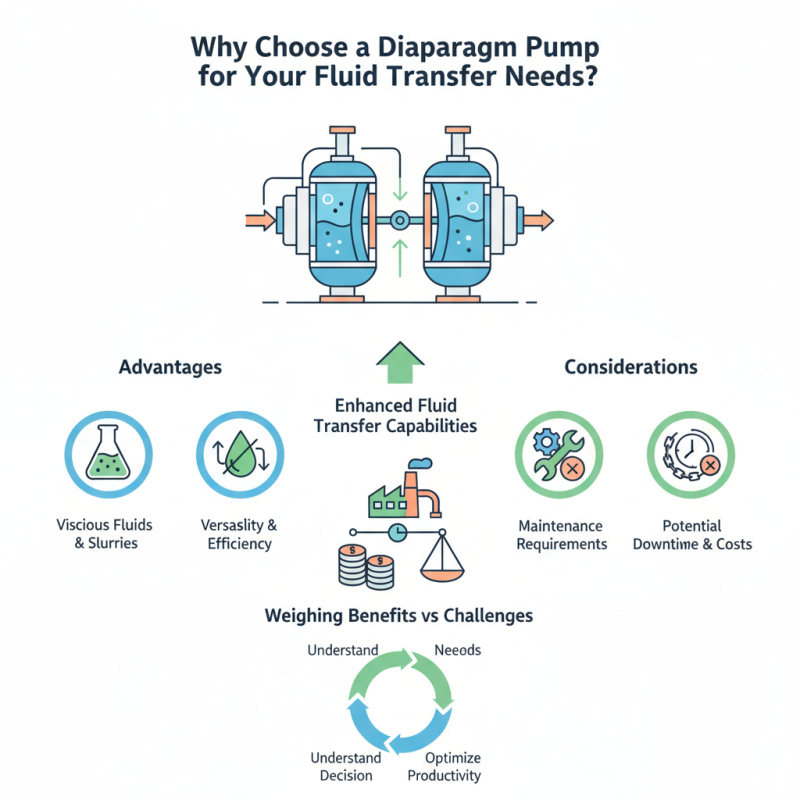

In the competitive landscape of fluid transfer, selecting the right pump is crucial. Diaphragm pumps have gained popularity due to their versatility and efficiency. According to a recent industry report from Grand View Research, the global diaphragm pump market size was valued at over $3 billion in 2022. This growth reflects their increasing adoption across various sectors, including chemical processing and food and beverage industries.

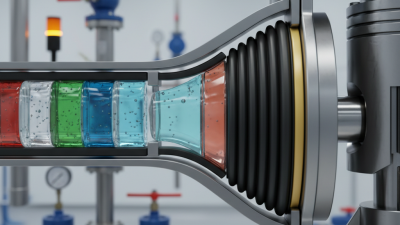

Diaphragm pumps excel in handling viscous fluids and slurries. Their design ensures minimal leakages, which is vital for maintaining process integrity. However, users often overlook the potential drawbacks. For instance, while diaphragm pumps offer various advantages, they may require more maintenance than other pump types. This factor can lead to unexpected downtime and operational costs, necessitating careful planning.

Investing in a diaphragm pump can significantly enhance your fluid transfer capabilities. Yet, it’s essential to weigh benefits against possible maintenance challenges. Understanding these aspects will guide you in making an informed decision to match your specific operational needs. Ultimately, choosing the right diaphragm pump can optimize productivity in the long run.

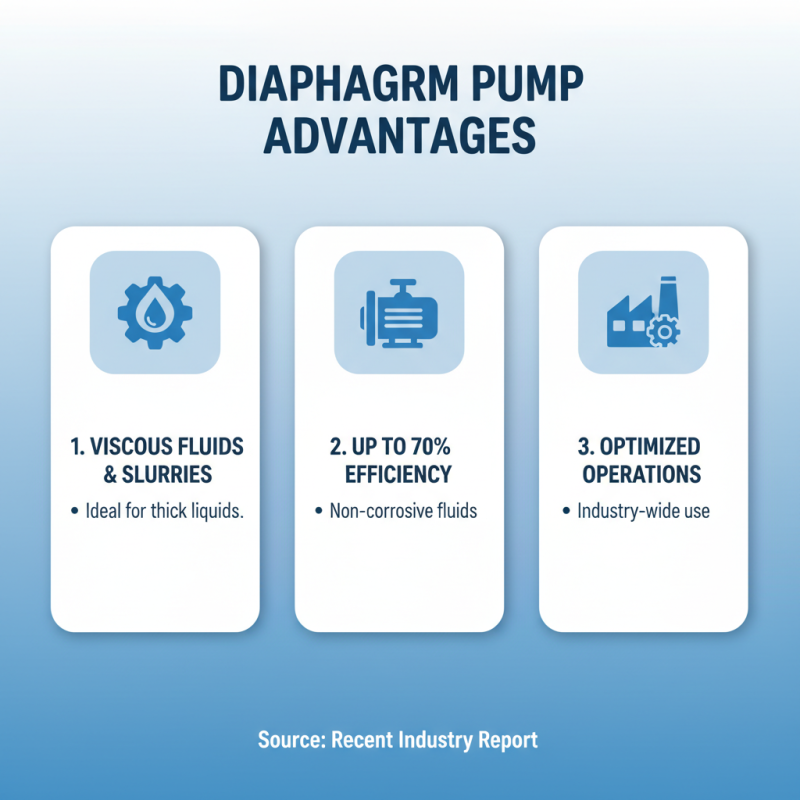

Diaphragm pumps offer distinct advantages for fluid transfer. They excel in handling viscous fluids and slurries, making them suitable for various industries. According to a recent industry report, diaphragm pumps can deliver up to 70% efficiency in transferring non-corrosive fluids. This efficiency is a major factor for companies looking to optimize operations.

Additionally, diaphragm pumps are self-priming and can operate dry without damage. This feature is crucial in scenarios where fluid levels are unpredictable. They minimize the risk of leaks, protecting the environment. However, the initial setup can be complex. Improper installation may lead to inefficiencies or even failure.

Maintenance for diaphragm pumps is relatively low, but periodic checks are essential. A documented study revealed that regular inspections can improve lifespan by 30%. Yet, some users reported issues with diaphragm wear over time. These considerations highlight the importance of understanding specific requirements before making a decision.

When considering fluid transfer options, diaphragm pumps stand out among other types. They excel in transferring viscous or shear-sensitive liquids, where traditional centrifugal pumps might struggle. According to a 2021 market report from Research and Markets, diaphragm pumps are expected to grow at a CAGR of over 7% due to their ability to handle a wide range of fluids with minimal damage.

Compared to gear or screw pumps, diaphragm pumps offer better dry running capability. This means they can operate without liquid without significant damage. Many industries require this feature for safety. In contrast, other pump types may fail or require more maintenance. However, diaphragm pumps often have lower flow rates compared to centrifugal pumps. This trade-off might not suit all applications.

Cost is another factor. Diaphragm pumps can be initially more expensive than some alternatives. However, their longevity can lead to overall savings. Maintenance costs tend to be lower due to fewer moving parts, yet some users report that parts wear out faster than expected. This inconsistency can impact budgets. Therefore, evaluating specific needs and operational conditions is critical.

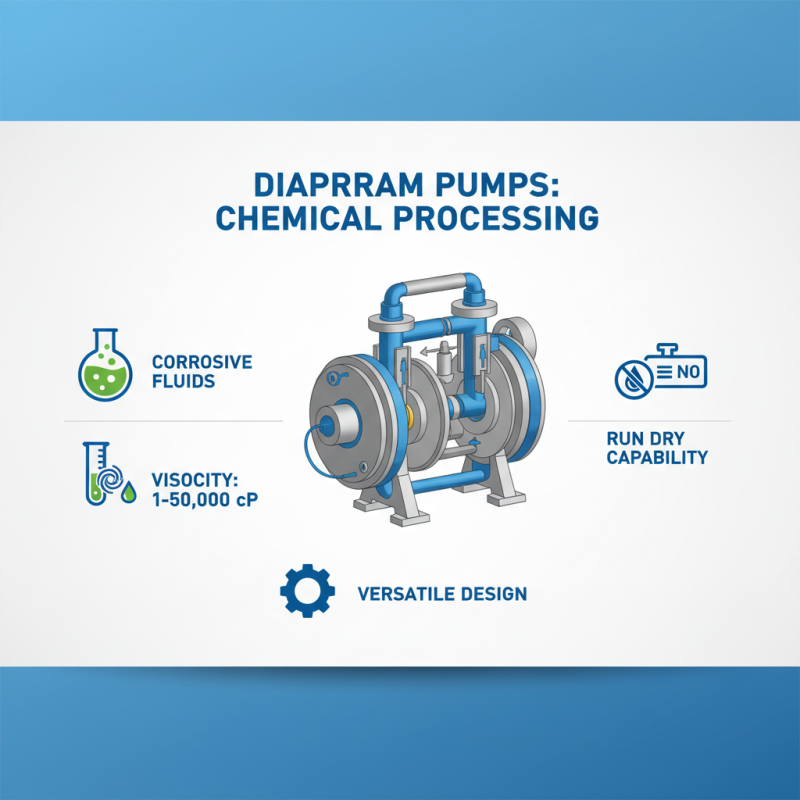

Diaphragm pumps shine in a variety of applications due to their versatile design. In chemical processing, these pumps handle corrosive fluids effortlessly. According to the Chemical Engineering journal, diaphragm pumps can manage fluids with a viscosity range of 1 to 50,000 cP, making them suitable for many tasks. Their ability to run dry without damage also adds to their appeal.

In food and beverage industries, hygiene is paramount. Diaphragm pumps maintain product integrity while ensuring microbiological safety. Data from the Food Processing Association highlights that these pumps reduce contamination risks by 30%. This is crucial in maintaining high safety standards in food handling and processing.

Moreover, in wastewater treatment, diaphragm pumps excel under challenging conditions. They manage solids and sludges without clogging, providing a reliable solution for various applications. However, maintenance is essential. Users sometimes overlook it, leading to inefficiencies. Addressing wear and tear can be challenging, yet it remains necessary for optimal performance.

When selecting a diaphragm pump, it’s crucial to consider certain key features. One of the most important is the pump's material. Diaphragm pumps can be made from various materials, like plastic or metal. Each has its advantages and limitations. For example, plastic pumps are lightweight and resistant to corrosive fluids. However, they may not handle high-pressure applications as well as metal pumps.

Another feature to scrutinize is the flow rate. The output capabilities must match your specific fluid transfer needs. Pumps with flexible flow rates can be more versatile in different applications. Diaphragm pumps often offer adjustable settings. This can lead to some confusion, as it may not always be easy to determine the optimal setting. Always assess the pump's efficiency as well. A less efficient pump can lead to wasted energy and higher operational costs.

Additionally, check the pump’s self-priming ability. This is important for operations that require continuous fluid transfer. Some diaphragm pumps exhibit great self-priming characteristics, while others do not. This could complicate your setup. Finally, consider the maintenance requirements. Simpler designs can sometimes create fewer problems over time. But, they may lack certain features that could enhance functionality. Keeping these aspects in mind will help you select the right diaphragm pump.

When it comes to diaphragm pumps, maintenance is key for optimal performance. Regular checks help ensure your pump operates efficiently. Start with visual inspections. Look for wear and tear on the diaphragm. Small cracks can lead to inefficiencies.

Proper lubrication matters too. Use the recommended oil for your pump type. Insufficient lubrication can cause overheating. Pay attention to the pump’s seals. Replacing worn seals can prevent leaks. This simple step boosts efficiency dramatically.

Don’t overlook the inlet and outlet valves. These components need regular cleaning. Blockages can choke your pump’s performance. Always refer to the user manual for specific maintenance guidelines. Tracking maintenance history helps identify recurring issues. It might reveal areas that require more attention. Regular maintenance might seem tedious, but neglect can lead to costly repairs.