Leave Your Message

Request a Quote

In an era where sustainability and efficiency are paramount, the selection of the right Filtration Bag is increasingly critical across various industries. According to a recent market analysis by Research and Markets, the global filtration industry is expected to reach $65 billion by 2025, driven by growing environmental awareness and stringent regulatory standards for waste management. This emphasizes the importance of choosing the appropriate filtration solutions to ensure optimal performance and compliance with safety regulations.

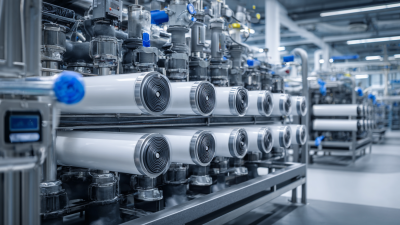

The rise in industrial activities and urbanization has led to an increased demand for effective filtration systems that can handle diverse applications, from air and water purification to industrial processes. A well-chosen Filtration Bag not only enhances operational efficiency but also contributes to reducing environmental impact. Studies indicate that the effectiveness of filtration can be significantly influenced by factors such as material composition, pore size, and flow rate, making it essential for businesses to thoroughly evaluate their specific needs in the context of their operational goals.

As we move closer to 2025, industries must remain proactive in adapting to these evolving challenges. Understanding the technical specifications and benefits of various Filtration Bags will empower stakeholders to make informed choices, ultimately advancing both productivity and environmental stewardship.

When selecting filtration bags for industrial applications, several critical factors must be considered to ensure optimal performance and efficiency. First and foremost, understanding the nature of the materials being filtered is essential. Different processes generate various types of particulates, and the filtration bag's material must be compatible with these substances. For instance, the choice of fabric—be it felt, mesh, or a synthetic blend—can significantly influence the bag's effectiveness and durability, making it crucial to match the material's properties with the specific application requirements.

Additionally, the filtration efficiency and micron rating play a vital role in the selection process. A thorough assessment of the desired level of particle retention is necessary to determine the appropriate bag specifications. Higher micron ratings can capture smaller particles, but may also lead to increased pressure drops, affecting overall system efficiency. Apart from filtration capabilities, factors such as the bag's size, shape, and structural integrity need to be evaluated, ensuring a proper fit within existing systems while maintaining robustness under varying operational conditions. By carefully considering these elements, industries can optimize their filtration processes, enhancing productivity and reducing maintenance costs.

This chart illustrates the importance of various factors when selecting filtration bags for industrial applications. Each factor is rated on a scale from 1 to 10, highlighting the significance of material type and filtration efficiency as key determinants in the decision-making process.

Understanding filtration efficiency ratings is essential when choosing the right filtration bag for your needs in 2025. Among the most recognized efficiency ratings are MERV (Minimum Efficiency Reporting Value) and HEPA (High-Efficiency Particulate Air). MERV ratings range from 1 to 16, indicating the filter's ability to capture particles of varying sizes. For instance, a MERV rating of 13 or higher effectively captures a significant percentage of airborne particles, including dust, pollen, pet dander, and even some bacteria and viruses. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), filters with a MERV rating of 8 or higher can significantly improve indoor air quality and reduce allergens.

HEPA filters, on the other hand, must meet specific standards, including trapping at least 99.97% of particles that are 0.3 microns in diameter. This makes HEPA filters exceptionally valuable in environments that require high levels of cleanliness, such as hospitals and laboratories. Recent studies indicate that using HEPA filters can reduce the airborne spread of pathogens, making them a crucial choice for enhancing air quality in both residential and commercial settings. Beyond MERV and HEPA, understanding other filtration technologies, such as activated carbon and electrostatic filters, can further assist users in making informed decisions tailored to their specific air quality needs.

When choosing a filtration bag, understanding the material types is crucial for ensuring optimal performance in various applications. The three most commonly used materials in filtration bags are polypropylene, polyester, and PTFE (Polytetrafluoroethylene). Each material offers distinct characteristics that cater to different filtration requirements.

Polypropylene filtration bags are known for their lightweight and cost-effectiveness, making them suitable for a wide range of general filtration tasks. They exhibit excellent resistance to acids and bases, which makes them a reliable choice in many industrial settings. However, polypropylene has a limited temperature tolerance, which may restrict its use in higher-temperature environments.

On the other hand, polyester filtration bags offer enhanced strength and durability compared to polypropylene. They are particularly well-suited for applications involving organic solvents and can withstand higher temperatures. Meanwhile, PTFE filtration bags stand out for their superior chemical resistance and non-stick properties, making them ideal for applications where contaminants might adhere to the bag's surface. The choice between these materials depends significantly on the specific requirements of the filtration process, including chemical compatibility, temperature, and the nature of the substances being filtered.

When selecting a filtration bag, understanding your equipment model is crucial to optimizing performance and efficiency. Different machines operate with varying requirements regarding filtration sizes and configurations. For instance, a system designed for fine particulate filtration may require smaller micron ratings, whereas larger filtration systems can often accommodate larger bag sizes, making it essential to match the bag to your specific equipment for effective operation.

Tips: Always consult the user manual of your equipment model to determine the recommended bag sizes and configurations. This will not only ensure compatibility but also enhance the filtration process, minimizing wear and tear on the machinery.

Moreover, consider the material of the filtration bag in relation to its intended application. For operations dealing with harsh chemicals or extreme temperatures, opting for materials designed to withstand such conditions is paramount. This choice can prolong the life of both the bag and the equipment, as well as maintain the quality of the filtration.

Tips: Before finalizing your purchase, assess the environmental conditions your filtration system will face. Choosing the right material can significantly influence the durability and performance of your filtration bag, ensuring it meets the demands of your operations efficiently.

Choosing the right filtration bag can have significant economic impacts on operational costs, especially in a landscape where efficiency is essential to maintaining a competitive edge. Selecting the appropriate filtration bag not only ensures optimal functionality but also helps in minimizing downtime and maintenance expenses. An efficient filtration system can lead to lower energy consumption and reduced waste disposal costs, translating to substantial savings over time.

When evaluating filtration bags, consider the material and design tailored to your specific application. Bags made from high-quality materials may come with a higher upfront cost but often yield increased durability and longer service life. This can lead to fewer replacements and lower labor costs related to routine maintenance.

Tips: Assess your filtration needs carefully and choose a bag that meets those needs effectively without over-specifying. Regularly reviewing your system's performance can also lead to adjustments that optimize your filtration process, further enhancing cost efficiency. Additionally, engaging with industry experts can provide valuable insights into the latest advancements in filtration technology, helping you make informed decisions that benefit your operational budget.