Leave Your Message

Request a Quote

In today's industrial landscape, air quality management has become a paramount concern, particularly in manufacturing and processing sectors. Effective Bag Filtration systems play a crucial role in maintaining clean air and enhancing operational efficiency. According to a report by the Air Quality Control Association (AQCA), improper air filtration can lead to a 20% increase in energy consumption and a significant decline in air quality, affecting both employee health and equipment longevity. Thus, optimizing Bag Filtration strategies is not only an environmental responsibility but also an economic necessity.

Industry expert Dr. Emily Thompson, a leading figure in air filtration research, emphasizes the importance of proper filtration practices stating, "Investing in advanced Bag Filtration technologies can significantly reduce airborne contaminants, ultimately leading to healthier environments and lower operational costs." This assertion is supported by studies indicating that businesses can see up to a 30% reduction in maintenance costs when effective filtration systems are implemented. As air quality regulations become more stringent and organizations strive to meet sustainability goals, understanding and applying essential Bag Filtration tips will be critical for improving overall air quality and operational efficiency.

Bag filtration plays a crucial role in maintaining and improving air quality, particularly in industrial and commercial environments. By capturing airborne particles, such as dust, allergens, and pollutants, bag filters help ensure cleaner air is circulated. This is essential not only for the health of individuals who occupy these spaces but also for compliance with environmental regulations. The effectiveness of bag filtration directly impacts the overall air quality, reducing respiratory issues and enhancing comfort levels.

Moreover, the efficiency of bag filtration systems contributes to energy savings and operational performance. When filters are functioning optimally, they allow for better airflow, reducing the strain on ventilation systems. This can lead to lower energy costs and prolonged equipment life. Regular monitoring and timely replacement of bag filters are fundamental practices that organizations should adopt to sustain air quality and system efficiency. Correctly understanding and implementing bag filtration techniques can thus lead to significant improvements in both air quality and operational productivity.

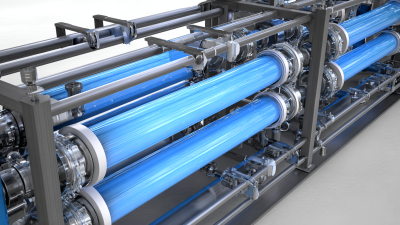

When it comes to air filtration, choosing the right bag filter is crucial for both efficiency and air quality. There are several types of bag filters available, each designed to address different needs based on the specific application. For instance, synthetic filters are great for high dust loads due to their durability and higher surface area, while washable filters offer a sustainable option that can be reused. Additionally, HEPA filters are ideal for environments requiring high indoor air quality, as they capture up to 99.97% of particles that are 0.3 microns in size.

To select the most suitable bag filter, consider factors such as the type of contaminants you expect to encounter, the air flow rate of your system, and maintenance requirements. Always pay attention to the filter’s efficiency rating and flow resistance, as these can significantly impact performance.

Tip: Regularly monitor and replace bag filters based on the manufacturer's recommendations or observed pressure drops in your filtration system. This proactive approach not only enhances air quality but also optimizes energy usage, leading to cost savings in the long run. For specialized environments, consult with experts who can offer tailored solutions that meet specific filtration needs.

Maintaining filter efficiency and longevity is crucial for ensuring optimal air quality and system performance. Regular inspections are the first step in this process. Checking for dirt accumulation and any signs of wear at least every month can prevent clogs that reduce airflow. When filters appear dirty or damaged, timely replacements are essential. Utilizing a schedule for filter changes not only helps maintain airflow but also improves the overall effectiveness of the filtration system.

Moreover, environment plays a significant role in filter maintenance. High levels of dust, pollen, or other particulates in the air can shorten a filter's lifespan. Therefore, using pre-filters or air purification systems can significantly enhance primary filter performance, capturing larger particles before they reach the main filter. Additional measures, such as ensuring proper sealing of the filter housing and optimizing system settings according to seasonal needs, further contribute to enhanced filtering efficiency and longevity, allowing for cleaner air and improved energy efficiency.

Bag filters are an essential component in maintaining air quality in various industrial and commercial applications. However, various common issues can arise that affect their performance and efficiency. One frequent problem is the accumulation of dust and debris on the filter media, which can lead to reduced airflow and increased energy consumption. Regular inspection and maintenance are crucial. Cleaning or replacing filters as needed can significantly improve air quality and extend the life of the filtration system.

Another common issue is the improper sealing of bag filters, which can lead to air bypass and decreased filtration efficiency. Ensuring that filters are installed correctly and that all seals are intact can help to mitigate this problem. Additionally, monitoring pressure drops across the filter can provide insights into performance issues; a sudden increase may indicate a blockage or that the filter needs replacement. Troubleshooting these issues promptly can help maintain optimal performance and prevent larger problems from developing.

Regular air quality monitoring is essential to maintaining a healthy indoor environment, especially when using bag filtration systems. By routinely checking the effectiveness of filters, homeowners and facility managers can ensure that any airborne pollutants are being effectively captured. The first step in this process is to establish a consistent schedule for inspections—ideally, filtering systems should be evaluated monthly. This will help identify any issues before they escalate, such as reduced airflow or decreased filtration efficiency.

In addition to regular inspections, utilizing air quality monitors can provide real-time data that aids in evaluating filter performance. These devices can pinpoint levels of particulate matter, humidity, and other factors that influence air health. By cross-referencing this data with filter replacement schedules, you can ascertain the optimal times for changing out filters, thus enhancing both air quality and energy efficiency. Integrating these best practices into your maintenance routine will not only improve the performance of your filtration system but also contribute to a healthier living or working space.

| Filter Type | Efficiency Rating (MERV) | Recommended Change Interval (Months) | Common Applications | Key Benefits |

|---|---|---|---|---|

| Fiberglass Filters | MERV 1-4 | 1-3 | Residential HVAC Systems | Low cost, effective large particle removal |

| Pleated Filters | MERV 5-13 | 3-6 | Homes, Commercial Buildings | Higher efficiency, longer lifespan |

| HEPA Filters | MERV 17-20 | 6-12 | Hospitals, Clean Rooms | Removes 99.97% of particles ≥0.3 microns |

| Electrostatic Filters | MERV 8-12 | 3-5 | Residential/Commercial HVAC | Reusable, effective against smaller particles |

| Activated Carbon Filters | N/A | 6-12 | Odor Control, Gas Filtration | Reduces odors and gaseous pollutants |