Leave Your Message

Request a Quote

Choosing the right bag filters is essential for optimizing industrial processes and ensuring environmental compliance. According to Dr. Emily Carter, a leading expert in industrial filtration systems, "The effectiveness of your filtration process heavily relies on selecting the appropriate bag filters tailored to your specific needs." As industries continue to evolve, so do the challenges they face in maintaining operational efficiency while adhering to stringent regulatory requirements.

Bag filters play a crucial role in various applications, from air pollution control to liquid filtration. Therefore, understanding the key factors in selecting the right bag filters can significantly impact an organization’s productivity and sustainability goals. By delving into considerations such as material compatibility, flow rates, and maintenance requirements, industries can make informed decisions that enhance their filtration strategies. This guide aims to provide essential tips that will assist in navigating the complexities of bag filter selection, ultimately leading to improved performance and cost-efficiency in industrial operations.

When it comes to industrial applications, choosing the right type of bag filter is crucial for optimal performance and efficiency. There are several types of bag filters available, each designed to meet specific filtration needs. For instance, polyester and polypropylene bag filters are commonly used due to their chemical resistance and durability, making them suitable for a range of industries. These materials can effectively capture particles while maintaining structural integrity in various operating environments.

Another important category is pleated bag filters, which offer a larger surface area compared to traditional flat bags. This design allows for enhanced dirt-holding capacity and longer service life, making them ideal for facilities with high dust loads. Additionally, there are activated carbon bag filters that are specifically designed for removing odors and volatile organic compounds (VOCs) from airflow, making them invaluable in environments that require high air quality standards. Understanding these different types of bag filters is essential for selecting the right one to match the specific needs of an industrial process, ensuring both efficiency and compliance with environmental regulations.

When selecting bag filters for industrial applications, the choice of filter media materials is crucial in optimizing efficiency and effectiveness. Various materials, including polyester, polypropylene, and activated carbon, offer different benefits depending on the specific filtration requirements. For instance, a recent industry report indicates that polypropylene filters are favored for their excellent chemical resistance and lower cost, making them ideal for a wide range of applications, particularly in the petrochemical sector. Meanwhile, polyester media provides enhanced durability and can withstand higher temperatures, which is essential for industries dealing with extreme conditions.

Further evaluation of the filtration process reveals that the efficiency of bag filters can significantly decrease due to particle loading and back pressure. According to data from the American Filtration and Separations Society, filters with a fine woven fabric or non-woven materials can achieve efficiencies of up to 99.9% for particulates larger than 0.5 microns. Choosing the right media involves considering the size and type of contaminants, flow rates, and maintenance intervals to ensure optimal operation. This ensures not only longer filter life but also reduced operational costs, an essential aspect in various manufacturing and processing environments.

This chart illustrates the efficiency of various filter media materials commonly used in industrial bag filters. The data reflects the average efficiency ratings based on independent testing of filter media used for different applications.

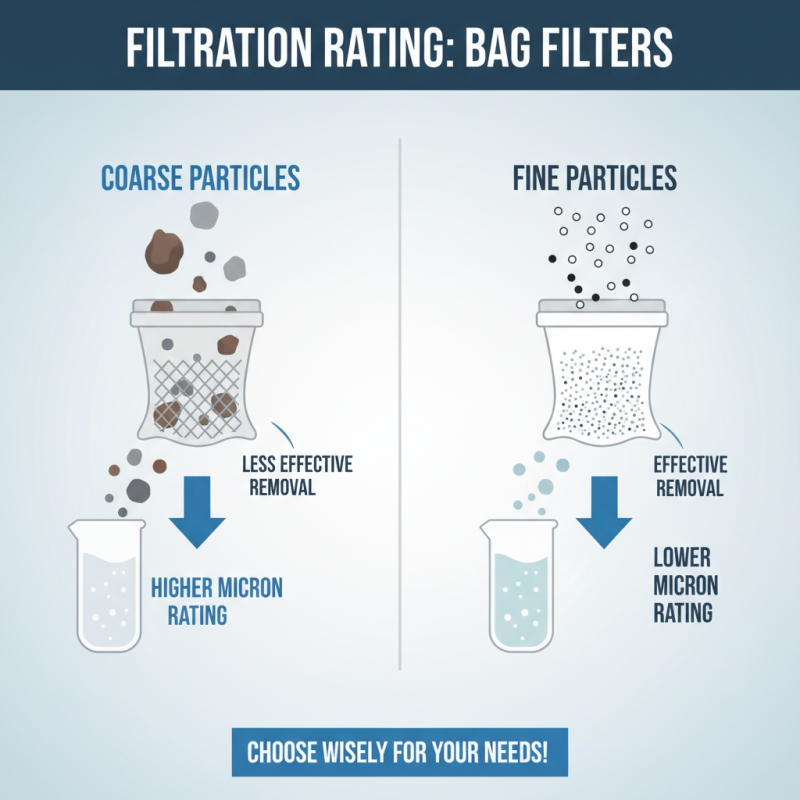

Choosing the right bag filters for industrial applications is heavily reliant on understanding the filtration rating necessary for your specific requirements. Filtration ratings serve as a measure of how effectively a filter can remove particles from the fluid being processed. This rating is often defined by the size of the contaminants the filter can capture; thus, it's imperative to consider the nature and size of particles present in your operation. For example, when dealing with coarse particles, a filter with a higher micron rating may suffice, while finer particles necessitate a lower micron rating to ensure effective removal.

Moreover, it’s essential to assess the operating conditions and the type of fluid to be filtered. Different applications may require filters that can endure varying temperatures, pressures, or chemical compositions. Understanding these factors not only aids in selecting a filter with the appropriate filtration rating but also ensures longevity and efficiency in the filtration process. Additionally, consulting expert guidelines or industry standards can provide clarity on the most suitable filtration options tailored to your operational needs. This thorough evaluation process will ultimately help in maintaining optimal performance and reliability in your industrial filtration systems.

When selecting the right bag filters for industrial use, it’s crucial to assess their compatibility with your existing systems and processes. This involves a thorough evaluation of the current setup, including the type of machinery in use, the materials being filtered, and the specific operating conditions, such as temperature and pressure. Understanding these elements ensures that the chosen bag filters will integrate seamlessly, avoiding disruptions in the workflow and maintaining optimal efficiency.

Additionally, it's important to consider the physical dimensions and connection types of the bag filters. They must fit perfectly into the pre-existing filter housing to prevent leakage and maintain the required airflow or liquid flow. Furthermore, compatibility with the filter media is essential; the selected filters should effectively capture the desired particulate size without compromising the overall functionality of the system. By prioritizing these aspects in the selection process, industries can enhance performance while minimizing the risk of contamination or system failure.

When budgeting for the installation and maintenance of bag filters in an industrial setting, it's essential to account for both initial costs and ongoing expenses. The installation costs typically include the price of the bag filters themselves, along with the expenses related to any necessary equipment modifications or enhancements to accommodate the new filtration system. It’s important to analyze whether existing infrastructure can support the new filters or if significant adjustments are needed, as these can considerably increase the overall budget.

Maintaining bag filters involves regular inspections and replacements, which should also be factored into your budget. Maintenance costs can vary depending on the operating environment and the type of materials being filtered. Establishing a routine maintenance schedule can help in foreseeing these expenses and ensuring that the filters operate efficiently, thus prolonging their lifespan and reducing long-term costs. An effective budgeting plan should therefore combine both installation and maintenance costs to provide a comprehensive view of the financial commitment required for implementing and sustaining an efficient bag filtration system.

| Tip Number | Tip Description | Budget Considerations | Maintenance Tips |

|---|---|---|---|

| 1 | Determine the type of particles you need to filter. | Consider costs associated with specific filtration requirements. | Regularly check filter condition to avoid sudden failures. |

| 2 | Assess your facility’s airflow requirements. | Plan for equipment upgrades if airflow exceeds current limits. | Keep airflow measurements up to date for optimal performance. |

| 3 | Evaluate the operating temperature and pressure conditions. | Select materials that withstand your specific conditions. | Inspect filter housing for signs of wear in extreme conditions. |

| 4 | Consider the size and dimensions of the filter. | Measure installation space accurately to avoid future issues. | Ensure proper sealing to avoid air bypass and inefficiency. |

| 5 | Select the right filter media for your application. | Evaluate cost vs. performance of different media types. | Schedule periodic cleaning or replacement based on usage. |

| 6 | Research filter efficiency ratings (e.g., HEPA, ULPA). | Higher efficiency may mean higher initial costs. | Monitor efficiency regularly to ensure proper filtration. |

| 7 | Look into the potential for filter recyclability. | Recyclable filters can reduce long-term waste costs. | Establish a recycling program for used filters. |

| 8 | Check the manufacturer’s warranty and support options. | Consider potential extra costs for extended warranties. | Utilize manufacturer support for maintenance guidance. |

| 9 | Consider the noise level produced by the filter system. | Noise-attenuating models may come at a premium. | Regular maintenance can minimize noise as components wear. |

| 10 | Seek feedback from other industry users or experts. | Learning from others can help prevent costly mistakes. | Implement suggestions to improve your filtration process. |