Leave Your Message

Request a Quote

In today’s industrial landscape, the significance of effective air and fluid filtration cannot be overstated, with bag filtration systems playing a pivotal role in ensuring compliance with environmental regulations and maintaining operational efficiency. According to a recent report by MarketsandMarkets, the bag filtration market is projected to reach USD 4.3 billion by 2026, driven by increasing industrial activities and a growing need for air quality management. Industries ranging from pharmaceuticals to food processing are increasingly adopting advanced bag filtration technologies to tackle particulate matter and enhance production quality.

This article presents seven essential tips for optimizing bag filtration systems, enabling industries to not only adhere to strict environmental standards but also to reduce operational costs and improve the overall performance of their facilities. As organizations strive for sustainability and efficiency, mastering bag filtration becomes more crucial than ever in navigating the complexities of modern manufacturing and processing environments.

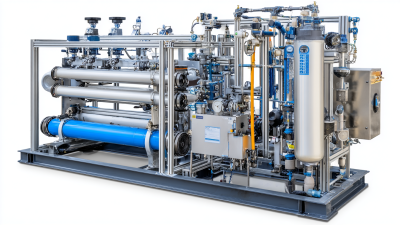

Bag filtration systems play a crucial role in various industrial applications by ensuring clean air and fluid processes. These systems effectively remove particulate contaminants from air and liquids, enhancing product quality and protecting equipment from damage. In industries such as pharmaceuticals, food processing, and chemical manufacturing, maintaining a high level of cleanliness is not just essential for compliance with regulations but also for operational efficiency.

Understanding the importance of these filtration systems goes beyond just knowing their function. Regular maintenance and optimization can lead to significant improvements in performance and cost savings. For instance, a well-optimized bag filtration system can increase the lifespan of filters, reduce energy consumption, and minimize downtime. By implementing strategies such as proper selection of filter media and regular monitoring of airflow and pressure differentials, industries can ensure their filtration systems operate at peak efficiency, leading to enhanced productivity and sustainability.

| Tip Number | Optimization Tip | Expected Benefit | Implementation Frequency |

|---|---|---|---|

| 1 | Regular Maintenance Checks | Improved filter lifespan | Monthly |

| 2 | Choosing the Right Filter Media | Enhanced filtration efficiency | Annually |

| 3 | Optimize Airflow Rates | Reduced operational costs | Quarterly |

| 4 | Regular Inspection of Bag Integrity | Minimized leaks and downtimes | Bi-weekly |

| 5 | Use of Pre-Filters | Increased overall filter performance | As needed |

| 6 | Monitor Dust Load and Flow Rate | Optimized cleaning cycles | Continuous |

| 7 | Implement Baghouse Control Systems | Automated and efficient operation | As recommended |

When selecting bag filters for your industry, it’s vital to focus on several key factors that will ensure optimal filtration and performance. First, consider the specific application and environment in which the filter will be used. For instance, industries such as pharmaceuticals or food processing require stringent filtration standards to avoid contamination. Reports indicate that the global market for bag filters is projected to exceed $3.8 billion by 2026, growing steadily due to the increasing demand for efficient filtration systems across various sectors.

Another essential factor is the filter media material. Different applications may require various materials to achieve the desired level of filtration efficiency. For example, synthetic materials often provide better durability and lifespan compared to traditional cotton filters. Additionally, it’s important to take into account the filter size and configuration, as these directly affect the flow rate and overall system efficiency. A recent study highlighted that improper sizing could lead to a drop in performance by up to 30%, emphasizing the need for precise calculations when selecting bag filters for your operations.

Regular maintenance and monitoring of bag filtration systems are crucial for ensuring optimal performance and longevity. One best practice is to implement a consistent inspection schedule. By routinely checking the condition of the filters and the overall system, any signs of wear or damage can be identified early, preventing more significant issues down the line. Keeping a maintenance log that records filter changes, cleaning schedules, and any irregularities observed during inspections can also help track the system’s performance over time.

Another key aspect of effective maintenance is monitoring the pressure differential across the filters. Changes in pressure can indicate an increase in particulate load or potential blockages, signaling when it’s time to replace or clean the filters. Utilizing smart sensors and automation technology can enhance this process, providing real-time data that can help operators make informed decisions. Additionally, regular training for personnel on proper maintenance techniques and the importance of following standard operating procedures can lead to significant improvements in filtration system efficiency and reliability.

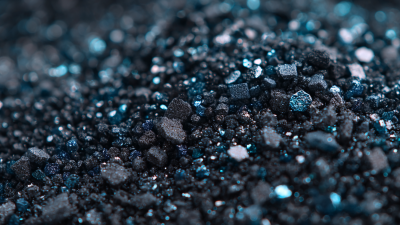

Innovative technologies are transforming bag filtration systems across various industries by enhancing efficiency and reducing operational costs. According to a recent study by the American Filtration and Separation Society, advancements in filter media, including nanofibers and advanced composites, have shown to improve filtration efficiencies by up to 30%. These modern materials not only capture smaller particles but also allow for higher flow rates, effectively reducing energy consumption.

Moreover, the integration of smart technology into bag filtration systems is becoming increasingly prevalent. Real-time monitoring and data analytics enable facilities to optimize maintenance schedules and predict filter replacement needs, resulting in extended filter life and minimized downtime. A report from the Global Filtration Market projected that the implementation of smart filtration technologies could reduce costs by up to 25% for companies in sectors such as manufacturing and food processing. By leveraging these innovative solutions, businesses can significantly enhance the performance of their bag filtration systems and achieve greater sustainability.

When optimizing bag filtration systems, it's crucial to be aware of common pitfalls that can hinder performance. One frequent mistake is disregarding the importance of regular maintenance and inspection. Over time, filters can accumulate debris and particulates, leading to reduced efficiency. Implementing a routine maintenance schedule ensures that your system operates at peak performance, minimizing downtime and unexpected failures.

Another mistake to avoid is neglecting to customize filter selection based on specific operational requirements. Not all filtration mediums are created equal; choosing the wrong type can result in suboptimal filtration and increased costs. Those who take the time to analyze their processes and select the appropriate bags tailored to their needs often experience improved filtration quality and longer filter life. Additionally, integrating customer feedback into system designs can significantly enhance effectiveness. Understanding end-users' experiences can guide better adjustments and innovations in filtration systems, ensuring they meet real-world demands.