Leave Your Message

Request a Quote

As we look ahead to 2025, the diaphragm pump industry stands at the brink of transformational advancements aimed at enhancing performance and efficiency. According to a recent market analysis by MarketsandMarkets, the global diaphragm pump market is projected to reach USD 6.5 billion by 2025, driven by the increasing demand for reliable fluid handling across various sectors, including water treatment, chemical processing, and pharmaceuticals. This growth highlights the significance of "精工细造,中国制造,服务世界," reflecting the commitment of Chinese manufacturers to innovate and adapt to global standards. Emerging technologies such as IoT integration and advanced materials are set to redefine diaphragm pump capabilities, ensuring superior performance and operational longevity. In this blog, we will explore the insights and innovations shaping the future of diaphragm pumps, positioning them as essential tools in a rapidly evolving industrial landscape.

As we look ahead to 2025, diaphragm pumps are set to undergo transformative advancements that promise enhanced performance and efficiency. Key to these innovations are developments in materials science, particularly the use of advanced composites that improve chemical resistance and durability. According to a recent industry report by MarketsandMarkets, the global diaphragm pump market is projected to grow from USD 2.12 billion in 2020 to USD 3.43 billion by 2025, underscoring the increasing demand for these efficient fluid handling solutions.

Moreover, smart technology integration is transforming diaphragm pump applications. The incorporation of IoT capabilities allows for real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs. A report from Grand View Research highlights that the smart pump segment is expected to grow at a CAGR of 15.6% from 2021 to 2028. This trend towards automation not only enhances efficiency but also provides operators with valuable data insights, fostering informed decision-making processes and improving overall system reliability.

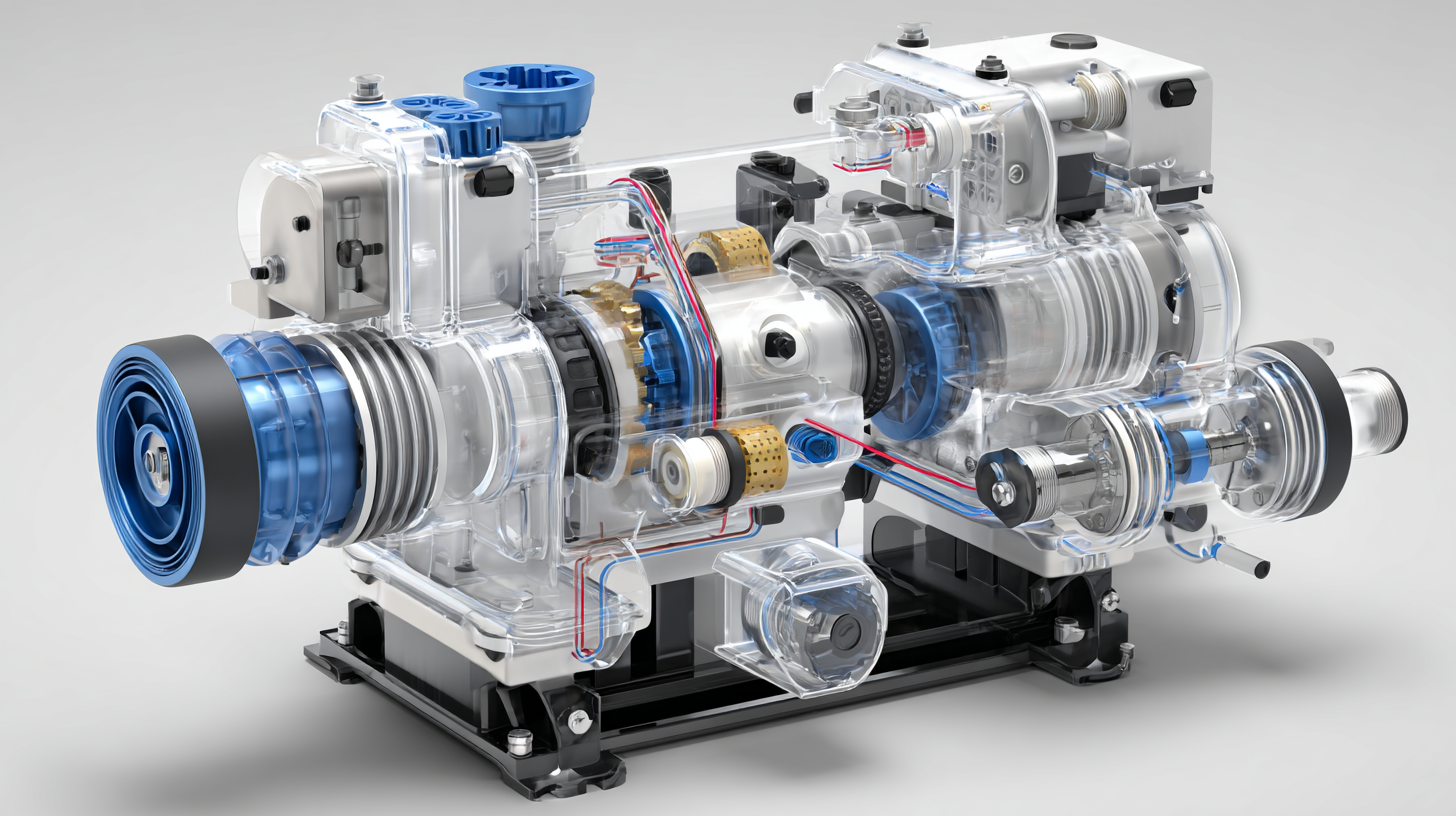

As we look toward 2025, the evolution of diaphragm pumps is being significantly driven by emerging materials that enhance efficiency and performance. Recent studies indicate that the global diaphragm pump market is projected to grow at a CAGR of 5.1%, reaching approximately $4.3 billion by 2025. This growth is largely attributed to advancements in materials such as reinforced polymers and elastomers that offer superior resistance to chemicals and temperature fluctuations. These innovations not only extend the lifecycle of diaphragm pumps but also minimize downtime and maintenance costs.

Moreover, companies are integrating lightweight composite materials into pump designs, leading to improved portability and ease of installation. According to a report by MarketsandMarkets, the use of advanced materials can improve energy efficiency by up to 25% in diaphragm pumps. The enhanced durability and performance characteristics offered by these new materials are pivotal for applications in sectors such as wastewater treatment, food processing, and chemical manufacturing, where reliability is crucial. As manufacturers continue to prioritize material innovation, the diaphragm pump landscape is poised for transformative changes that will redefine operational efficiencies in various industries.

| Emerging Material | Impact on Efficiency (%) | Durability (Years) | Cost (per unit) | Thermal Resistance (°C) |

|---|---|---|---|---|

| Advanced Polyethylene | 15 | 10 | $120 | 70 |

| Reinforced Elastomer | 20 | 12 | $150 | 80 |

| Carbon Fiber Composite | 25 | 15 | $250 | 90 |

| PTFE (Teflon) | 18 | 20 | $200 | 200 |

| Synthetic Rubber | 10 | 8 | $80 | 60 |

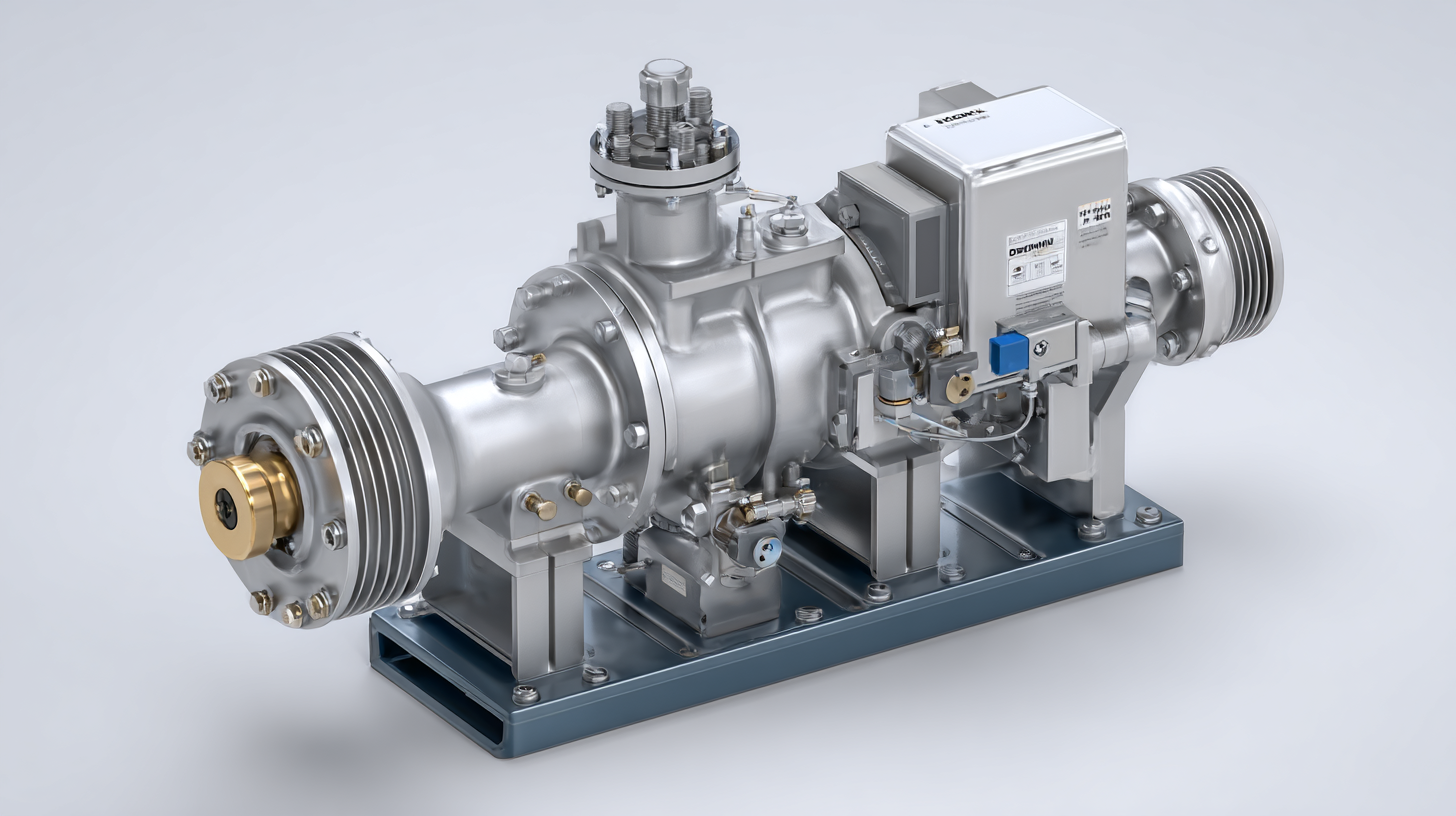

The diaphragm pump industry is poised for significant advancements by 2025, driven by innovative designs aimed at enhancing durability and overall performance. According to a recent report by MarketsandMarkets, the global diaphragm pump market is projected to grow from USD 4.2 billion in 2020 to USD 6.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.1%. This growth is largely attributed to innovations in materials and engineering processes that enhance the resilience of diaphragm pumps under extreme operating conditions.

One notable trend is the integration of advanced composite materials, which not only improve the pump's resistance to corrosive substances but also reduce weight and energy consumption. New design methodologies, such as 3D printing and computer-aided simulation, are also streamlining the production process, enabling manufacturers to create bespoke solutions tailored for specific industrial applications. This improved design flexibility allows for more robust systems capable of handling higher pressures and varying flow rates, ultimately leading to superior performance and reliability in challenging environments. As these innovations unfold, they will undoubtedly redefine the standards for diaphragm pumps in multiple sectors, including chemical processing, food and beverage, and healthcare industries.

As we delve into the future of diaphragm pumps, particularly through the lens of market trends projected for 2025, we encounter significant insights that highlight the evolving landscape of pump technology. The diaphragm pump sector is poised for growth, driven by applications in water treatment, chemical processing, and even the burgeoning hydrogen fuel industry. The surge in demand for sustainable energy solutions, coupled with the rapid development of hydrogen refueling stations, underscores the importance of reliable and efficient diaphragm pumps in these systems.

Tips: When selecting a diaphragm pump, it is crucial to consider factors such as fluid compatibility and maintenance requirements. Manufacturers are increasingly focusing on innovations that enhance durability and reduce downtime, which can significantly impact overall operational efficiency.

In addition, the ongoing trends in the ISO and ANSI pump markets indicate a growing inclination towards automated systems. The integration of smart technologies within diaphragm pumps can optimize performance and facilitate real-time monitoring. Businesses looking to invest in diaphragm pumps should stay informed about these advancements to ensure they are making the best choices for their operational needs.

As we navigate towards 2025, the diaphragm pump industry is poised for significant advancements driven by sustainability and environmental considerations. Recent reports indicate that the global diaphragm pump market is projected to reach $5 billion by 2025, with a notable shift towards eco-friendly materials and designs. Manufacturers are increasingly focusing on reducing energy consumption and emissions, ensuring that their products not only perform efficiently but also adhere to global sustainability standards.

Innovations such as the introduction of biodegradable diaphragms and recyclable components are gaining momentum. A recent survey noted that 72% of pump manufacturers are prioritizing green technologies in their product development strategies. By integrating advanced materials that minimize waste and enhance durability, the industry is not just improving performance but is also committing to environmental stewardship.

**Tip:** For those in the market for diaphragm pumps, consider suppliers that emphasize sustainability in their offerings. Look for certifications that reflect eco-friendly practices, as these not only benefit the environment but can also lead to long-term cost savings through improved efficiency.

Furthermore, enhancing the energy efficiency of diaphragm pumps is becoming a focal point, with research showing that energy-efficient pumps can reduce operating costs by up to 30%. With this emphasis on performance coupled with sustainable practices, the future of diaphragm pumps looks bright, ensuring a balance between innovation and environmental responsibility.

**Tip:** Always ask for energy efficiency ratings and sustainability reports when sourcing diaphragm pumps to ensure you are making a responsible investment.